About Macrodyne Technologies Inc.

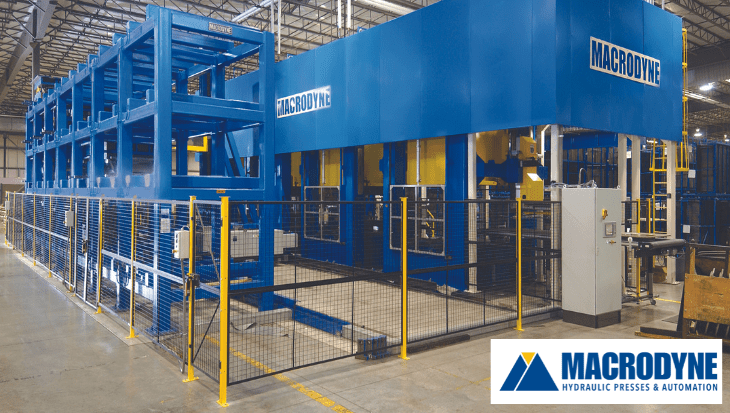

Macrodyne Technologies Inc. is an Engineer To Order company that designs and manufactures high quality custom hydraulic presses, press lines, and die handling equipment for customers worldwide. Industries include automotive, aerospace, industrial & consumer products, defense, construction, and more.

In business since 1990, and with a focus on quality and innovation, Macrodyne Technologies has developed a solid reputation in the industry, leading to a large repeat customer base, and continued growth.

Size of Company

90+ employees

Industry

Design and manufacturing of heavy duty, high quality hydraulic presses up to 20,000 ton capacity, and press line automation, and die handling equipment up to 100 tons.

Location

Concord, Ontario, Canada

CAD

SOLIDWORKS

AutoCAD Electrical

Accounting

QuickBooks

Business Challenge

Macrodyne Technologies needed a more effective way to operate their Engineer To Order business. They needed to move away from their paper-centric process and better prepare, store, access, and report on, their data.

Solution

Macrodyne Technologies realized Total ETO would address all their issues and more. The ability to scale up with Total ETO, as well as the quick implementation timeline, and cost effectiveness of the solution were all key factors to making the purchase.

Dynamic Benefits and Results

- Time savings through efficiency

- Cost savings

- Visibility on part tracking

- Powerful reporting

- Timekeeping

- Ease of implementation

- Support from Total ETO

Business Challenge

Macrodyne Technologies recognized they needed a more effective way to operate their Engineer To Order business. Hundreds of BOMs, RFQs, and POs are created daily, either in excel or handwritten documents. Often, their press designs are built off aspects of prior designs, making the ability to find historical data critical.

Creating reports required searching through all their paperwork, trying to identify the correct information. With no consistency in part numbers or descriptions, finding specific data was both time consuming, and difficult. Macrodyne Technologies needed to find a better way to store, access, and repurpose their data.

Solution

After investigating several options they narrowed down their choice to Total ETO.

Recommended by Jeremy Neil, Executive Vice President, and, Stan McLean, their Engineering Manager they realized it would address all their issues and more. The ability to scale up with Total ETO, as well as the quick implementation timeline, and cost effectiveness of the solution were key factors.

Dynamic Benefits and Results

Time savings through efficiency

The implementation of Total ETO has resulted in an overall streamlining for all departments involved. As a result, projects and orders now flow through the organization with minimal disruption, allowing everyone to access the same, consistent information.

Searching historical data is easy and fast. Pulling up prior designs from the SolidWorks tie in allows Engineering to repurpose the information and save time. Now Engineering can compile their own BOMs quickly and push them to purchasing when ready.

Purchasing can consolidate multiple BOMs into single RFQs and POs for efficiency, and issue and modify them with a few keystrokes. With no manual data entry, the purchasing team now has more time to manage other duties.

With all systems tied in to Total ETO, associated drawings and documentation can be linked to projects, and automatically attached to RFQs and POs.

Cost savings

Total ETO is a cost effective solution for Macrodyne Technologies. By consolidating part orders to obtain best pricing on bulk orders, purchasing can pass this savings along to the customer. Unused materials can be tracked and redirected to future projects. For a business focused on maintaining a worldwide reputation for value, this efficiency is critical.

Visibility on part tracking

With Total ETO, part tracking is easy and can be done at any point during a project. Supply chain management is easy for engineers trying to determine the status and pricing of a specific PO. Parts can be sorted by part number, project, assembly, vendor, etc.

Powerful reporting

Macrodyne can now run reports can be run with the click of a button. With over 200 pre-designed reports, and the ability to create new ones means they can present the information when, and how they require. In addition, reports can be exported directly to Excel, Word, PDF, and email.

Timekeeping

Total ETO integrates with Quickbooks providing Macrodyne with a full picture of their jobs current and past, filtering them as desired to see labor costs.

Ease of implementation

The Total ETO system was implemented live allowing the team to benefit immediately, and the staff has found the system straightforward and easy to work with. The videotaped training sessions are being used for on-boarding new employees.

Support from Total ETO

Macrodyne has been pleased with the support they’ve received from Total ETO and have found the Total ETO staff to be a great resource to work with in ensuring the solution works the way they need it to.