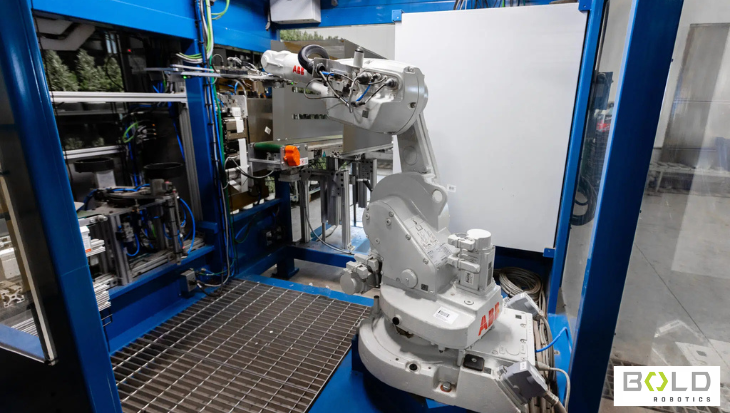

Bold Robotics provides cost-effective, smart machines that can reduce labor dependencies for greenhouses and nurseries.

Bold Robotics, Ontario, Canada

“It makes everything easier at the end of the day to be profitable”.

Geoff Hofsink, Mechanical Design

Size of Company

< 10

Location

Vineland, Ontario, Canada

CAD

SOLIDWORKS

Accounting

Quickbooks Online

Business Challenge

Bold is a small but strong team. Most staff had double duties, including redundant clerical work that took too much time. They also struggled with project visibility. At the end of some projects, there wasn’t enough information available to determine an ROI. The team also knew they needed to improve their procurement process, including tracking parts; too much time and money was being lost. Additionally, while Bold wanted to grow their business, they couldn’t because the team was too busy. They simply didn’t have the production capacity to take on more projects.

Solution

The team at Bold is benefiting from their new, enhanced, full-project visibility. This is already improving efficiency and accuracy when estimating new projects. Bold is also saving time and money in procurement. Total ETO takes care of many time-consuming jobs, such as ordering and tracking parts; the team is happy to have those removed from their “to-do lists”. Furthermore, additional money is saved from not having to expedite shipping. Plus, with the redundant clerical work eliminated, engineering and management have a lot of time freed for better things, such as taking on additional projects.

Dynamic Benefits & Results

- Significantly reduced time in procurement with less time tracking parts, too.

- Full project visibility with real-time info is improving their project completion time.

- Significant savings on both labor and parts as well as warranties.

- The ability to take on more projects, increasing their annual throughput.

BUSINESS CHALLENGES

Slowdowns in Purchasing

The team at Bold knew their workflow needed improvement. One of their biggest inefficiencies was in procurement. Ordering and tracking parts was difficult. As Geoff Hofsink, Mechanical Designer at Bold said, for a medium-sized project, it would take him a couple of days just entering the parts, going back and forth between SOLIDWORKS and some Excel spreadsheets. They needed to eliminate a lot of excessive steps.

Not Enough Data or Project Visibility

Custom Machine Builders like Bold often struggle with full project visibility, including the costs involved with the project. During, and even after a project finished, there wasn’t enough information available to confirm a profit. That same valuable data could also help the sales team, providing more efficient and accurate estimates. However, there was no effective way to gather and report this important data.

Labor was too High

Bold is a small team, and many of the staff members, including the owners, share double duties. That means everyone was bogged down with redundant clerical work. With engineering and management spending time chasing parts and handling POs and change orders, there wasn’t much time to think about growing the organization. Additionally, their team was so busy, they didn’t have the production capacity to take on more projects.

DYNAMIC BENEFITS AND RESULTS

Less Procurement for Everyone

With most of the team ordering their own parts for a project, it took a lot of valuable time away from engineering and management. Time that would have been better spent designing additional automation solutions, for additional clients. Now, they can do just that! All of the redundant clerical work is gone, along with the typos are transposition errors that came with it. The team also doesn’t waste time every week tracking parts. Purchasing and inventory are now a smooth ecosystem that saves Bold time and money.

Reduced Labor and Project Completion Times

Hofsink estimates each employee saves 2-3 weeks a year now, simply from reduced clerical work. With engineers and owners ordering their own parts, tracking them down, and entering them into the system, these key employees weren’t being used to their full potential. Redundant clerical work was costing the team money every week. When those steps were eliminated by Total ETO, Bold Robotics could take on more projects throughout the year. As Geoff Hofsink, Mechanical Designer at Bold, said, “Those engineering hours that were spent doing data entry can now be spent designing new machines, new layouts, and being more productive for the bottom line.” It also made work more enjoyable for the team as they were able to focus on what they love – designing and customizing solutions.

Full Visibility

Bold loves and is thriving from the new, enhanced, full-project visibility. Such real-time info can help improve project completion time, prevent mistakes, and help future similar projects. With the info you collect from each job, sales can take estimated costs and quickly add a margin or fixed dollar price for quoting. It’s also easy to copy similar project elements from past projects using budget or actual costs.

Savings

It didn’t take long after implementation for Bold Robotics to start saving time and money. Money spent on labor was reduced because Total ETO does most of the time-consuming jobs for them, such as ordering and tracking parts. Money is also saved because the team doesn’t need to rely on expedited shipping. Now, with their ERP, parts are ordered and tracked, keeping each project on time and within budget. They’re also able to bulk order common components. Additionally, Bold is using Total ETO to track warranties on parts, adding to their savings over the long term.

“It makes everything easier at the end of the day to be profitable”.

Geoff Hofsink, Mechanical Design