About EAGLE Technologies Group

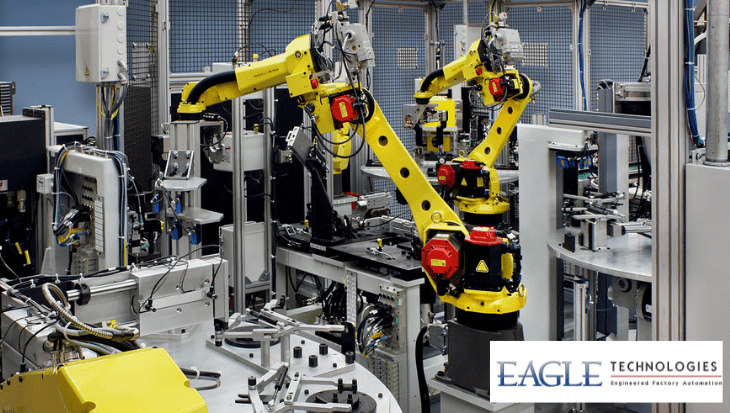

EAGLE Technologies Group located in Bridgman, Michigan has been supplying world-class manufacturing and engineering design, equipment and services to its customers since 1953. They are experts in assembly, test, vision, robotics, and material handling systems.

Size of Company

250+ employees

Industry

Robotics and Material Handling Systems

Location

- Bridgman, Michigan

- Manufacturing Facility-255,000 sq. ft. facility with state of the art CNC machining centers

CAD

SOLIDWORKS

Accounting

QuickBooks

Business Challenge

EAGLE Technologies needed a system that allowed visibility to the whole company. Engineers wanted the Bill Of Materials (BOM) creation to be integrated so that purchasing had up to date information.

Solution

Total ETO’s automation software is an ERP solution designed by engineers for engineers. The BOM and purchasing link forms the backbone of the entire application for EAGLE Technologies, allowing purchasing to reference key information that was entered by engineers on RFQs and POs.

Dynamic Benefits and Results

- Project visibility at all stages of production

- Individual responsibility for time cards

- A seamless integration with SolidWorks

- Truly ETO software

- Exemplary customer service

Business Challenge

While EAGLE Technologies had a system in place, it lacked key functionality.

Bill Of Materials (BOMs) were created in Excel and engineers were afraid to submit them until they were complete. Change requests took a long time to make it to purchasing, often resulting in project delays and increased costs.

Accounting was responsible for manually entering timesheets for all 125 employees, a job which was time consuming and pulled their focus from their other duties.

They needed a solution that provided all staff access to project visibility, time sheet entries, and allowed engineers to release and edit multiple BOMs to others in a timely manner.

Solution

Several engineers at EAGLE Technologies had used Total ETO previously and knew it would solve their issues.

Total ETO has been an integral part of EAGLE Technologies growth since implementation. Improved efficiency has enabled the company to double in size to 250 employees, all using the automated Engineer To Order system, and in turn to take on increasingly more jobs.

Dynamic Benefits and Results

Project visibility at all stages of production

To run a successful Engineer To Order business requires project status visibility for all departments. With Total ETO, BOM changes are automatically visible to purchasing, allowing engineers the flexibility of releasing partial BOMs. Purchasing can now procure parts at the best price, ensuring materials are available when needed, which results in projects being delivered on time and within budget.

Individual responsibility for time cards

With all 125 staff entering their own time sheets, the accounting team has saved over 830 hours of administrative work a year. This frees up their time to spend on higher priority and more strategic business activities.

A seamless integration with SOLIDWORKS

Total ETO has true integration capabilities with SOLIDWORKS. With a dynamic BOM process, Total ETO allows the flexibility to not only create but also change a project’s BOM prior to, during, and even after its release from manufacturing to purchasing. All staff, including purchasing and management can monitor a projects’ progress, and make adjustments as required.

Truly ETO software

The decision to purchase Total ETO as their Engineer To Order system was “a no brainer”, according to Jason Cleveland, VP of Engineering at EAGLE Technologies Group. Not only were 30% of their staff familiar with the product, but two of the nearby competitors were also making the decision to move forward with Total ETO.

Exemplary customer service

EAGLE Technologies has been very pleased with the implementation and support from Total ETO. The solution was customized to suit their environment and help them reach their full potential, and regular product updates ensure that EAGLE Technologies continues to receive best value for their investment.