About TriTed Innovations Inc.

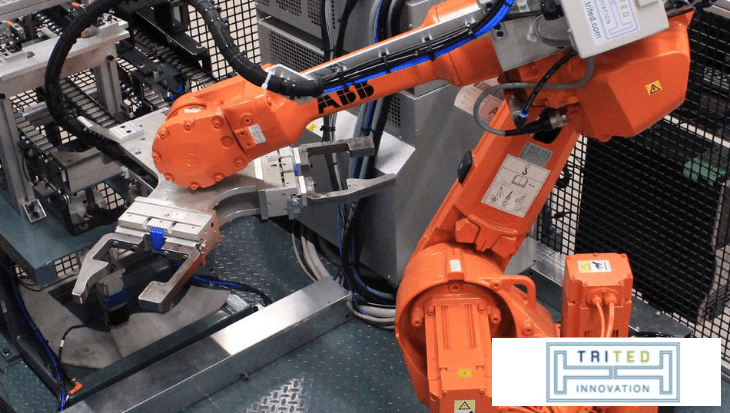

TriTed Innovations Inc. specializes in the automation of production lines ranging from the automotive industry to the pharmaceutical sector. With years of experience and quality assurance in robotic cells, vision systems, material handling and consulting, TriTed can provide the right solution to any type of manufacturing situation.

Size of Company

15-20 employees

Industry

Design and manufacturing of robotics and custom made automation systems

Location

Cambridge, Ontario, Canada

CAD

SOLIDWORKS

Accounting

QuickBooks

Business Challenge

In 2008 when Mehrdad Tufani started TriTed with Miro Pantic, he immediately contacted Total ETO to purchase the ERP and MRP system as he knew that it was the right solution for his Engineer To Order company.

Solution

Implementing Total ETO allowed TriTed Innovation to grow considerably into a mid-sized Engineer To Order company servicing North America.

Dynamic Benefits and Results

- Increase in efficiency and fewer errors

- Eliminate engineering to purchasing bottleneck

- Better communication

- Robust reporting center

- Great return on investment

- Truly Engineer To Order software

Business Challenge

TriTed relied on Excel to capture information, but data accuracy was an issue, and this approach was time consuming, inefficient, and often led to inaccuracies.

Timely release of Bill Of Materials (BOMs) and handling change requests posed a challenge for TriTed. Engineering held onto BOMs too long, for fear change requests would occur as the project evolved. As a result, purchasing often received the BOM too late to purchase on time or to obtain competitive pricing. This in turn delayed manufacturing and increased project costs.

Making an investment in software can be intimidating for any company, but for startups, the cost can seem even more overwhelming as it eats into the precious profits for the first few years.

TriTed needed a reliable, affordable software solution that was designed for their specific Engineer To Order business processes and that could help them grow from a start up to a successful mid-sized company.

Solution

Mehrdad Tufani has built a career working at manufacturing firms with different ERP solutions. Introduced to Total ETO at a previous position, he was impressed with how the software solution mimicked the process of a custom design manufacturer. Starting TriTed in 2008 he quickly implemented Total ETO to help him grow his company. Today TriTed Innovation has grown considerably into a mid-sized Engineer To Order company servicing North America.

Dynamic Benefits and Results

Increase in efficiency and fewer errors

Making the move away from Excel spreadsheets has led to increased efficiency and accuracy. All employees see and use the same information, in the same system, in real time. The data can be pulled and manipulated as needed to provide the appropriate information or run reports.

Eliminate engineering to purchasing bottleneck

Total ETO’s dynamic integration with purchasing means designers can create BOMs quickly, and confidently release and update the data as needed throughout the life of the project. Total ETO’s unique “hold and release” system provides designers with unparalleled control of the release of BOM items and assemblies to purchasing. The communication between engineering and purchasing is seamless, and purchasing is able to obtain best pricing on materials.

Better communication

For TriTed, the purchase of Total ETO has eliminated miscommunication between departments. One system for all information means that anyone can check in at any time to see the status of any project, part order, etc.

Robust reporting center

Total ETO’s Crystal Reporting engine allows management to obtain any information they need quickly. With over 200 pre-designed reports, all customizable, TriTed can report on all aspects of their business.

Great return on investment

For Mehrdad, the decision to purchase Total ETO was easy – “the software pays for itself as you save on admin costs”, Mehrdad states. The decision was a good one and with Total ETO, TriTed is prospering and confidently managing the next phase of their business growth.

Truly ETO software

Total ETO has been created by engineers with the input of Engineer To Order companies and therefore mimics the unique way those companies operate. After working with several ERP solutions at past companies, Mehrdad understood the value of a truly Engineer To Order solution and it was the reason he chose Total ETO when he started his own company.