About Hart Design & Manufacturing

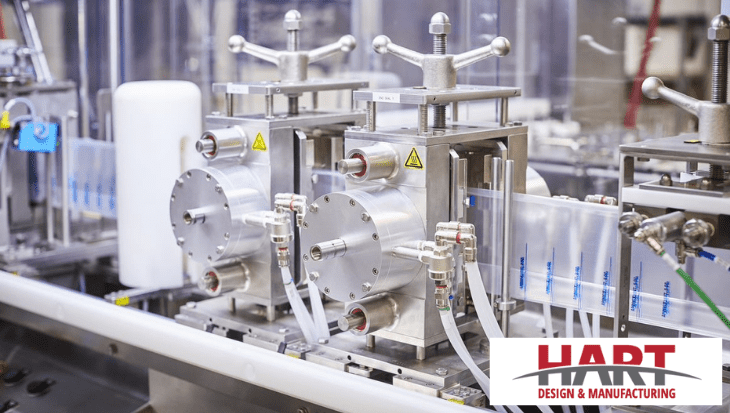

Hart Design & Manufacturing Inc. is a leader in the design and construction of specialty, standard and proprietary equipment for use in the Food and Dairy Industries. They have designed quality cheese processing and packaging equipment since 1975.

Size of Company

45 employees

Industry

Food and Dairy Industry

Location

Green Bay, Wisconsin

CAD

SOLIDWORKS

AutoCAD Electrical

Accounting

Sage 50

Business Challenge

Hart Design & Manufacturing was using an Access database and Excel spreadsheets to gather data. Mistakes were happening and time was being wasted.

Solution

Total ETO was quickly implemented in March 2013 and provided Hart Design & Manufacturing with the one touch point database it needed to streamline all data.

Dynamic Benefits and Results

- Streamline all data entry

- Eliminate duplicate data entry

- Seamless integration with SolidWorks

- User friendly software

- Save staff time

- Non conformance reporting (NCR)

- Solution understands Engineer To Order practices

Business Challenge

Hart Design & Manufacturing was using several different tools to collect project data. Some employees entered data in an access database while others used a number of excel spreadsheets. This caused time waste and entry errors.

It was critical that the ERP solution Hart Design & Manufacturing chose be able to integrate with their SOLIDWORKS CAD system.

Solution

Hart Design & Manufacturing considered 20 potential systems, and ultimately awarded the contract to Total ETO, the only vendor to use data from Hart Design & Manufacturing. By doing so, “Total ETO proved that their nomenclature was similar to what Hart Design & Manufacturing did,” said Timm Schaetz. “By using our data Total ETO proved that it would integrate seamlessly into our business practices.”

Integration with SOLIDWORKS was key for Hart, and Total ETO’s 20 years of experience integrating with the system proved it was the right fit.

Total ETO was quickly implemented in March 2013 and provided Hart Design & Manufacturing with the one touch point database it needed to streamline all data.

Dynamic Benefits and Results

Streamline all data entry

Total ETO’s central database means all staff are using the same version of data. Duplicate entries and clerical mistakes are eliminated, and staff can be assured that the data is pure and accurate.

Eliminate duplicate data entry

Total ETO completely eliminated double entry – employees enter all data into Total ETO easily, and there are no more duplicate entries, clerical mistakes or data omissions being made.

Seamless integration with SolidWorks

Total ETO’s true 3D CAD integration capabilities allows the flexibility to no only create, but change a project’s BOM prior to, during, and after its release to purchasing and manufacturing. BOMs can be linked to specific projects and adjusted as designs change.

User friendly software

Developed for the Engineer To Order industry, Total ETO mimics the way custom design manufacturers run their business and therefore is very intuitive. Total ETO was quickly implemented and its graphical and easy to use interface meant all 22 users were able to quickly start using the system.

Save staff time

Hart Design & Manufacturing employees now save time by only entering data into one database. Employees can pull pricing information 100% faster and job costing much faster.

Non-conformance reporting

A big benefit of Total ETO was its Non-Conformance Reporting feature (NCR). This feature allows staff to easily issue non-conformance reports for any parts that have been delivered with defects or quality control issues. POs are tagged and suppliers tracked for performance related issues.

Solutions that understand ETO practices

Total ETO understands the custom design manufacturing process and has been developed specifically for this industry. Hart Design & Manufacturing has benefited from purchasing a system that understands their specific business needs.