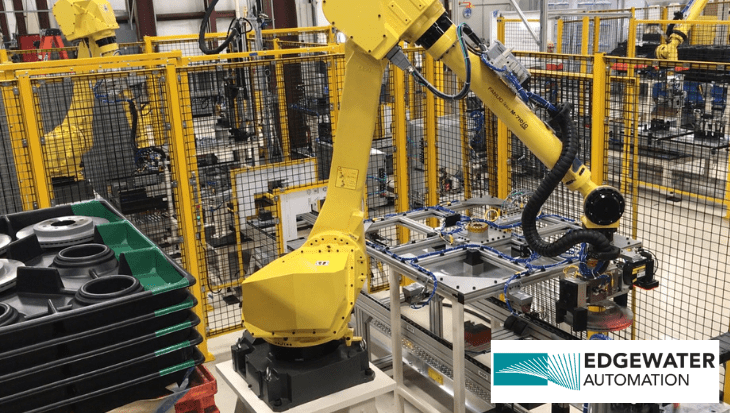

About Edgewater Automation

Edgewater Automation is a uniquely experienced designer and builder of custom automation equipment with locations in St. Joseph, Michigan and Spartanburg, South Carolina. Their innovative solutions address the challenges their customers face in today’s dynamic global manufacturing environment. The goal of Edgewater Automation is to provide quality equipment and elegant solutions that will help ensure the success of each customer.

Size of Company

250+ employees

Industry

Assembly and Test Equipment

Locations

St. Joseph, Michigan

Spartanburg, South Carolina

CAD

SOLIDWORKS

Accounting

QuickBooks

Business Challenge

Edgewater Automation required better tracking and integration with their accounting system.

Solution

Total ETO is specifically designed for the custom design manufacturer. Our system integrates your whole business from prospecting to shipping.

Dynamic Benefits and Results

- Better job quoting

- Reliable tracking of committed costs

- Better project management

- Streamline all data entry

- User friendly software

- True Engineer To Order solution

Business Challenge

Prior to purchasing Total ETO, Edgewater Automation used a standard accounting package to track all purchases and job costs. Although it was a good accounting package, it was unable to provide several key functions including; tracking of committed costs, tying into time tracking, and integration with a purchasing system. These issues led Edgewater Automation to source an Engineer To Order ERP and MRP system that would allow management to track purchasing and job costs.

After a thorough technical investigation of features, and a visit to three Total ETO clients, Rick Blake was satisfied that Total ETO was the perfect solution for their needs.

Solution

A Total ETO customer since 2006, Edgewater Automation has grown from 40 employees to over 200 employees in four locations. The system has handled this growth with ease, and is designed to continue scaling to future growth.

Total ETO has solved the issues Edgewater Automation was looking to address and more.

Dynamic Benefits and Results

Better job quoting

Edgewater Automation is often asked to quote “same but different” systems. The ability to search historical records for similar machines and engineering specifications allows them to quote more accurately, and allows Engineering to reduce design time and risk. Improving estimates, quoting, and manufacturing, results in higher profits.

Reliable tracking of committed costs

Total ETO provides users with reliable tracking of committed costs at any point during a project, including costs spent, costs committed, and actual costs after the job is shipped. This valuable information means that managers and accounting will always know if a project is on budget.

Better project management

Total ETO provides managers and key staff with better project management. Tracking and analyzing where projects, jobs, assemblies, or individual parts are, in real-time, allows managers to identify potential issues and take corrective action.

Streamline all data entry

It was key to Edgewater Automation to streamline all their data in a single database. Streamlining the flow of information through integration eliminates errors and speeds up the order to shipment process. It also frees up critical staff from routine clerical tasks to focus on their skills.

User friendly software

When Total ETO was initially implemented, Edgewater Automation had 40 employees. As the company has grown to over 200, new employees have been brought on without issue, finding the system to be user friendly and easy to use. Total ETO works with all customers to ensure new modules and tools are understood, and that the system is being used to its full potential.

True ETO solution

Created specifically for the Engineer To Order manufacturing industry, Total ETO is a true Engineer To Order ERP and MRP system, and all of our customers are Engineer To Order manufacturers. Edgewater Automation is satisfied that Total ETO understands their business and supports their success.